Soldering 101 For The Beginner

Safety First!

Before we even begin to discuss soldering a few notes about safety are in order. The tip or working end of a soldering iron gets hot! The tip temperatures can exceed 750 Degrees F or about 400 Degrees C. These temperatures can not only cause nasty burns but literally start a fire. The object of good soldering is to frequently join two or more wires together or mount electrical / electronic components. We will not be discussing soldering as it pertains to plumbing. The object is not to acquire a severe burn or burn your dwelling down.

Never and I mean absolutely never walk away from a heated soldering iron. Too frequently at the ring of a telephone or doorbell people abandon a heated energized soldering iron with the intent or returning momentarily. It only takes a moment for a disaster to happen and you return to a fire. Use a holding device for the heated iron to prevent burns to yourself and the work surface.

Never inhale the fumes during the actual soldering process. During the soldering process some smoke will be generated as the flux in the solder burns a little. The smoke is not only irritating to the respiratory system but can be toxic as well. Keep your head and field of view to the side of your work avoiding the smoke. The smoke is also irritating to the eyes.

Wear safety glasses! Though small soldering jobs seldom result in any solder splatter the possibility exist. A hot iron with solder on the tip can accidentally fall emitting tiny molten droplets of solder. Those droplets can cause severe eye damage.

Solder contains lead and lead is a toxic metal. Cleanliness is important. Wash your hands before and after handling solder. I say before because your hands contain natural oils which can impede good soldering if it gets on the solder. I say after for health reasons, again solder contains toxic alloys.

Never allow the hot element to come in contact with the units power line cord. I have seen countless power cords on soldering irons and stations burned to where the metal in the wires is exposed creating both a shock hazard and fire hazard.

Never work on energized electrical circuits. Be sure that no power is present on any circuits or wires you are soldering or working on.

Soldering is a skill!

Soldering is a skill and an easily mastered skill. Practice makes perfect holds very true in the art of soldering. Do not expect perfect results at first attempts when soldering. I suggest practicing with several pieces of scrap wire or some scrap boards. Your soldering skills will improve with time and practice. Only once good results are obtained should one begin working on important projects. Patience and practice will bring about great results and allow you to develop sound and safe soldering skills.

Soldering Equipment!

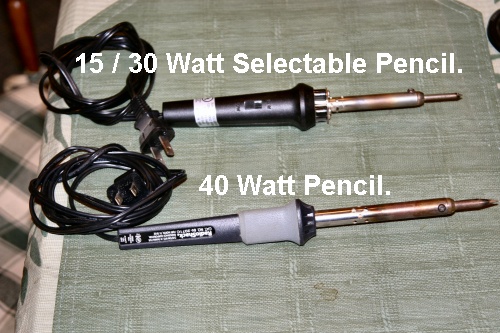

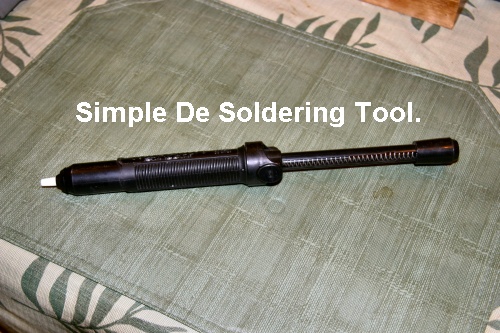

The following are examples of some soldering tools as well as a simple de soldering tool. Soldering irons or pencils can come in a variety of flavors for assorted soldering task. They also can carry a wide price range based upon features.

This is an example of a controlled heat soldering station. The user can adjust a heat set point and the actual soldering pencil will maintain that heat. The station includes a nice (and safe) holder for the pencil. These units also accept a variety of pencil tips for doing special work. Though a very nice to have tool, units like this carry a hefty price tag and are not really a practical investment for a home electronics or computer enthusiast. We are going to focus our attention on a few units more practical for the hobbyist and very reasonably priced.

Here we have a few "soldering pencils" as they are frequently called. These units run in the $8.00 to $15.00 price range and happen to be sold by Radio Shack. The 15 / 30 watt unit is the ideal unit for just about all home hobbyist. Though not adjustable controlled heat, the unit has a switch for selecting a low or high (15 or 30 watt) heat range. These ranges are ideal for most basic applications. The lower 40 watt pencil is great for soldering heavy wires or larger jobs requiring higher heat. These units are very reasonably priced and do allow for tip replacement with very inexpensive tips. We will be working with both of these units.

Let's take a look at some very basic solder. Solder comes in a very wide variety of "flavors" with literally countless pages of text written about it. We will focus on using basic 60/40 (tin/lead) solder meaning the alloy consist of 60% tin and 40% alloy. This solder for the diameter we will be using has a melting point of about 446 degrees F. (440 C.) It is an all around good general purpose solder for most applications. Also pictured is a spool of "lead free" solder which is a popular alternative to using solder containing lead as an alloy. As we move towards a green environment we can expect to see more and more of a movement to the elimination of lead (Pb) in our soldering products. Additionally there are solders containing silver used in special applications. Again, for our basic applications we will employ the KISS (Keep It Simple Soldering) principal. Spools of solder such as those pictured also come in a variety of diameters. For years Kester has been a leading name in solder and solder related products, for more information about solder I suggest their website: http://www.kester.com/en-us/products/index.aspx.

Another very useful tool when soldering is a de soldering tool. This tool is used when we want to remove components or parts from circuit boards. They come in several flavors and designs. The pictured unit consist of a spring loaded plunger in a tube that locks. Pressing a small button on the handle releases the plunger and the device will suck up molten solder. We will be using this tool in conjunction with a soldering pencil.

To Be Continued!

Today is 14 March 2008

Ron