Thermocouple Temperature Measurement

NOTE: Please keep in mind that endless white papers and

pages of text can be written on temperature. I have no intention of going to

deep into every aspect of temperature and temperature measurement.

Introduction:

The purpose

and scope of this blog is to create an open look at temperature and

temperature measurement. What I hope to accomplish is a broad overview of

the more common methods of temperature measurement and uncertainties of the

measurement process. I hope to focus on one of the most common temperature

sensor types, the Thermocouple. The primary focus will be placed on the

tried and true thermocouple, likely the longest living temperature sensor

and among the most common. We will look at thermocouple placement,

thermocouple signal conditioning and considerations in choosing a

thermocouple type for a specific application.

History:

While not

quite the accurate temperature measurement we have today the actual concept

goes back to around the year 1592.

Galileo is actually credited with the earliest methods of temperature

measurement. The following is taken from Agilent Technologies Application

Note 290:

“In an open container filled with colored alcohol, he suspended a long

narrow throated glass tube, at the upper end of which was a hollow sphere.

When heated, the air in the sphere expanded and bubbled through the liquid.

Cooling the sphere caused the liquid to move up the tube. Fluctuations in

the temperature of the sphere could then be observed by noting the position

of the liquid inside the tube. This “upside-down” thermometer was a poor

indicator since the level changed with barometric pressure and the tube had

no scale. Vast improvements were made in temperature measurement accuracy

with the development of the Florentine thermometer, which incorporated

sealed construction and a graduated scale”.

For all intensive purposes that was the first liquid in glass thermometer

used for temperature measurement. I only mention this because for those with

children seeking a good science fair project the evolution of temperature

measurement makes for an interesting project. Some off the shelf isopropanol

alcohol and some food coloring with tygon tubing and a basic crude liquid

thermometer can be built. Over the years scales were developed. One scale,

however, wasn’t universally recognized until the early 1700’s when Gabriel

Fahrenheit, a Dutch instrument maker, produced accurate and repeatable

mercury thermometers. Mercury in glass thermometers served hundreds of years

as precision laboratory grade thermometers for accurate temperature

measurement and comparison purposes.

Laboratory Grade Thermometer Sets

Definitions and Terminology:

Throughout

this blog we will be using some terms and definitions. To avoid confusion we

should clarify those terms now as they apply to this blog. I will try to

make the definitions short and sweet.

1.

Accuracy:

Unbiased precision with a high measure of repeatability..

2.

Calibration:

That which is a comparison of a known to an unknown value of measurement.

3.

Resolution:

The ability to read an

instrument or of the instrument to be read.

The Thermocouple:

When two

wires made of dissimilar metals or alloys are joined at both ends and one of

the ends is heated an electric current flows in the loop. This becomes a

thermoelectric circuit. Thomas Seebeck made this discovery around the year

1821 and it is known as The Seebeck Effect. Note that there is a current

flow in the following thermoelectric circuit.

Figure 1

All dissimilar metals exhibit this effect. However,

certain combinations when paired have become the combinations used for our

more common thermocouples. They and their respective milli-volt outputs may

be seen in the following illustration.

Figure 2

Enter the different types of thermocouples. The chart in

figure 2 shows the six most common metal combinations used for making

thermocouples. They are given Type Designations and the chart shows Type E,

J, T, K, R and S type thermocouples. The chart also plots the milli-volt

output against temperature. This type of data becomes very important in

helping a designer choose a thermocouple for a desired range of temperature

and output. Thermocouple types are chosen based on their intended

application! Let’s take a look at the actual alloys that comprise these

thermocouple types.

Type Metals:

E

Chromel

(+) vs. Constantan (-)

J Iron (+) vs. Constantan (-)

K Chromel (+) vs. Alumel (-)

R Platinum (+) vs. Platinum 13%

Rhodium (-)

S Platinum (+) vs. Platinum 10%

Rhodium (-)

T

Copper (+) vs. Constantan (-)

While the milli-volt output of thermocouples is non-linear in nature they do

have somewhat linear regions. This is another important factor in choosing a

thermocouple for a desired application. Let’s take a look at the linearity

curves shown in figure 3.

Figure 3

We notice that the slope of the type K thermocouple approaches a constant

over a temperature range from 0°C to 1000°C. Consequently, the type K can be

used with a multiplying voltmeter and an external ice point reference to

obtain a moderately accurate direct readout of temperature. That is, the

temperature display involves only a scale factor. While that looks good it

is not quite true. Yes, a type K thermocouple does have a nice linear range

it is far from flat. Thermocouple outputs, all thermocouple outputs are a

non linear voltage out function. Therefore linearization is always necessary

for a thermocouple if we expect to achieve any accuracy.

CJC (Cold Junction Compensation):

Earlier we mentioned and explained the Seebeck Effect and used a small

illustration to show it. Let’s take a look at connecting a thermocouple to a

voltmeter (figure 4) and see what really happens. We know a junction of two

dissimilar alloys or metals form a thermoelectric junction so let’s see what

is really involved with measuring a thermocouple output accurately. We will

be using a Type K thermocouple for our example but the same rules would

apply for any thermocouple.

Figure 4

Measuring the output milli-volts of a thermocouple is not as easy or simple

as it may seem. Look at figure 4 and we notice junctions 2 and 3. We created

those junctions when we connected our copper DMM leads to the actual

thermocouple alloy leads. The actual hot junction is the thermocouple; the

cold junction is where the thermocouple alloys mate with or connect to the

DMM leads.

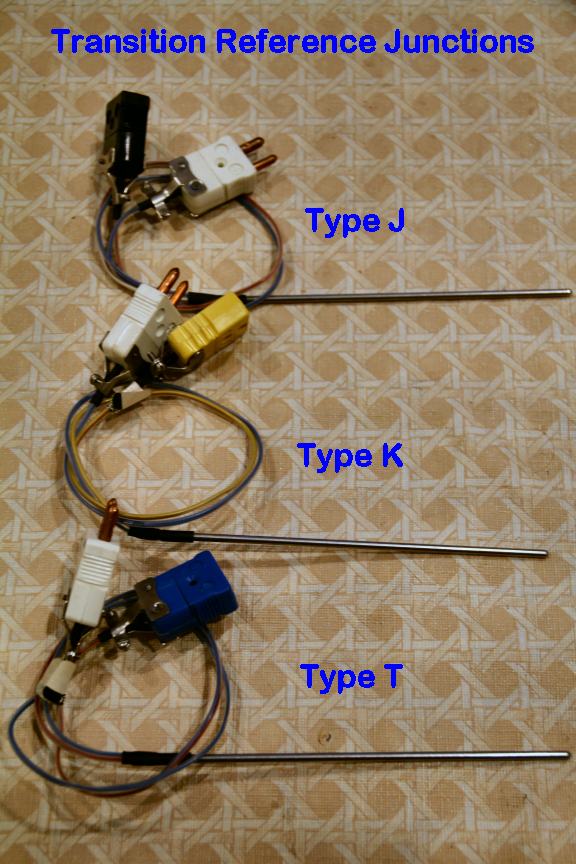

Accurate thermocouple

temperature measurement requires a stable reference junction. It is common

practice to create a transition reference junction by attaching a copper

lead wire to each thermocouple leg. When the transition reference junction

is held at the ice point 0°C (32°F) the output of the thermocouple appearing

across the copper leads attached to the readout instrument is stable and

predictable. This is only provided for reference as devices as seen in

Figure 5 would not be all that common outside a lab environment where

thermocouples were actually calibrated. They would represent Junction 2 and

Junction 3 in figure 4.

Figure 5

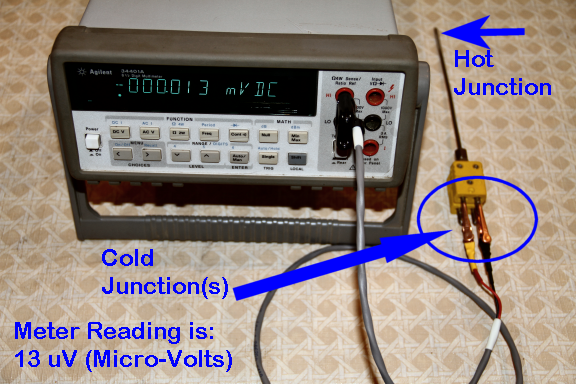

Let’s take a

look at an actual photograph of what Figure 4 would look like. The

thermocouple is a generic Type K thermocouple, laying on a table at room

temperature. The DMM is using copper clips connected directly to the

thermocouple.

Figure 6

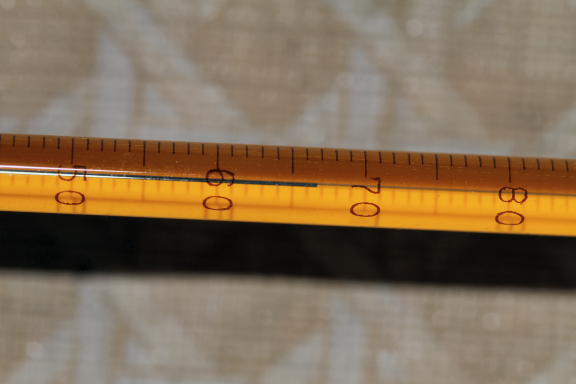

The ambient room

temperature is about 67 degrees F (19.44 C) and I know this to be true

because I measured it with precision mercury in glass calibrated laboratory

grade thermometer. Figures 7 & 8 illustrate how this is done. The

thermometer bulb is placed directly on the junction and allowed to

stabilize. This is shown in Figure 7 and the temperature is shown in Figure

8.

If I look up

a Type K temperature table I see that for my temperature I should be reading

about 0.776 mV which is far from my reading. However, the table also tells

me something else:

TEMPERATURE IN DEGREES °F

REFERENCE JUNCTION AT

32°F

My reference junction is not at 32 degrees F (0.0 degrees C) but at about 67

degrees F (19.44 C). This is where people always seem to go wrong when using

thermocouple to milli-volt tables. They neglect that reference junction

statement and that leads to errors. Even if I heat the hot junction the room

temperature or better said, the cold junction temperature will create a

large error.

Figure 7

Figure 8

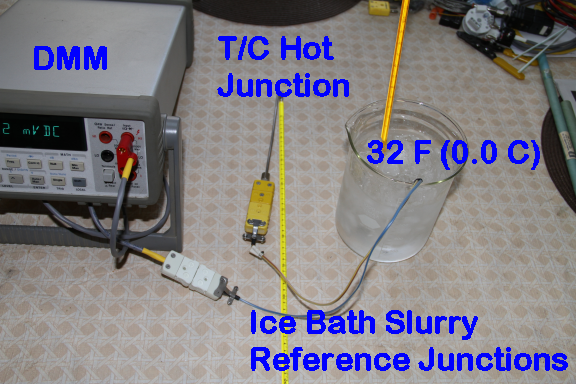

Now let’s

do this again but this time paying attention to CJC and seeing the

importance of CJC in the measurement. We will use the same setup as used in

Figure 6 but this time we will apply a reference junction temperature of 32

degrees F (0.0 C) as called out n the thermocouple reference tables. To

accommodate the cold junctions we will use a really simple and cheap ice

bath and the transition reference junctions shown in Figure 5. Those

familiar with this sort of measurement will be quick to point out the ice

bath should be in a Dewar’s (Vacuum) Flask and yes, the ice and water should

be distilled. For our learning purposes rest assured (I wouldn’t lie to you)

that a bucket of ice and Cleveland, Ohio USA tap water is just fine. There

are also various electronic ice point references out there, the Omega TRC

III comes to mind but we are not going to delve into them. The transition

reference junctions could also be easily made. I have some commercial

versions so I used them. Figure 9 represents our new and improved

measurement setup.

Figure 9

My ice bath

thermometer reads 32 degrees F (0.0 degrees C) and my hot junction

thermometer reads 65 degrees F (18.33 C). We exit our Type K thermocouple

using thermocouple alloys and go into the ice bath where copper alloy mates

with the T/C alloys at a temperature of 32 degrees F (0.0 degrees C) and

pass the signal along to our DMM. Let’s take a look at Figure 10.

Figure 10

Earlier I mentioned the

precision thermometer measuring the T/C hot junction was reading 65 degrees

F (18.33 C). If I return to my Type K reference tables I see the milli-volt

output for 65 degrees F (18.33 C) should be 0.731 mV which is exactly what

we have. Go figure huh?

The results

of this little kitchen table experiment even surprised me. Considering my

ice point reference was nothing special and considering the allowable error

of the actual thermocouple I did not expect to get results within one degree

F. I submit this as proof that even a blind squirrel finds an occasional

acorn.

While pages

and pages of text can be written about CJC the objective here was to give

you the reader a very basic overview of what CJC is and one method to apply

it. I believe we can see as demonstrated the importance of CJC and how it

applies to the measurement plane. It is not as simple as measuring a T/C

output using a DMM to measure temperature. We will see more about CJC as we

continue but for now we will take a look at Thermocouple Accuracy or

Uncertainty.

Thermocouple Accuracy &

Specifications:

Before we

even begin to look at just how good a T/C measurement can be I want to

clarify something. When it comes to the measurement plane I see accuracy as

a qualitive term that denotes a degree of quality, I see error as a

quantative term which may be expressed numerically. I cringe when I hear

someone say the accuracy of an instrument is +/- 1% of reading or full

scale. That tells me the instrument is only 1% accurate with an allowable

error of 99%. That said, we will move along to

the accepted allowable uncertainties of thermocouples. Let’s also look at

some general T/C specifications. We will look at T/C types J, K and T.

Type J:

MAXIMUM TEMPERATURE RANGE

Thermocouple Grade

32 to 1382°F

0 to 750°C

Extension Grade

32 to 392°F

0 to 200°C

LIMITS OF ERROR

(Whichever is greater)

Standard: 2.2°C or 0.75%

Special: 1.1°C or 0.4%

COMMENTS, BARE WIRE ENVIRONMENT:

Reducing, Vacuum, Inert; Limited Use in

Oxidizing at High Temperatures;

Not Recommended for Low Temperatures

TEMPERATURE IN DEGREES °C

REFERENCE JUNCTION AT 0°C

Type K:

MAXIMUM TEMPERATURE RANGE

Thermocouple Grade

– 328 to 2282°F

– 200 to 1250°C

Extension Grade

32 to 392°F

0 to 200°C

LIMITS OF ERROR

(Whichever is greater)

Standard: 2.2°C or 0.75%

Above 0°C

2.2°C or 2.0% Below 0°C

Special: 1.1°C or 0.4%

COMMENTS, BARE WIRE ENVIRONMENT:

Clean Oxidizing and Inert; Limited Use in

Vacuum or Reducing; Wide Temperature

Range; Most Popular Calibration

TEMPERATURE IN DEGREES °F

REFERENCE JUNCTION AT 32°F

Type T:

MAXIMUM TEMPERATURE RANGE

Thermocouple Grade

– 328 to 662°F

– 200 to 350°C

Extension Grade

– 76 to 212°F

– 60 to 100°C

LIMITS OF ERROR

(Whichever is greater)

Standard: 1.0°C or 0.75%

Above 0°C

1.0°C or 1.5% Below 0°C

Special: 0.5°C or 0.4%

COMMENTS, BARE WIRE ENVIRONMENT:

Mild Oxidizing, Reducing Vacuum or Inert; Good

Where Moisture Is Present; Low Temperature

and

Cryogenic Applications

TEMPERATURE IN DEGREES °C

REFERENCE JUNCTION AT 0°C

All thermocouples support data like this

and this data plays a pivotal roll in thermocouple selection for a given

application. Beginning with the Maximum Temperature Range we see over what

range of temperatures which thermocouples are suited. Actual thermocouple

wire comes in several different grades which define the quality of the

actual wire. Thermocouple Grade wire is what the

name implies. The wire is manufactured to meet standard limits of error for

the T/C type. Special limits wire is a higher purity grade of wire with, as

can be seen, closer limits of error. Extension grade is just wire used

between a thermocouple and the instrument reading the thermocouple.

Pay attention

to the limits of error. Without special calibration what you see is what you

get. People frequently will state they wish to use a Type K thermocouple and

achieve an uncertainty of +/- 0.1 degree F or C. This is unrealistic as a

change of 0.1 degree C amounts to a change of about 4

uV in the thermocouple output. When

choosing a thermocouple for an intended application we need the thermocouple

to meet or exceed our range and uncertainty requirements.

When we see a

reference to Bare Wire this means the base alloy thermocouple with the

junction exposed to the atmosphere the thermocouple is used in. For example

a Type J thermocouple is made from Iron and Constantan alloy. A bare wire

Type J thermocouple would not be a good choice in a moist environment as the

iron would be prone to rust and corrosion. This would only be true when the

actual thermocouple alloy is exposed or bare. There is likely no limit to

the number of ways thermocouples can be constructed.

Making

A Thermocouple:

Since we

know a thermocouple is a junction of two dissimilar alloys if we have some

thermocouple wire we can build a thermocouple at the kitchen table. We will

start with a few lengths of bare Type K thermocouple wire.

Figure 11

Worth noting is when using Type K T/C wire the Negative lead is

magnetic. This is useful as both alloys look the same, also worth noting is

in the case of a Type J T/C the Positive lead is magnetic. The wire used

here is AWG 12 (2.05 mm) which is pretty thick stuff but this thermocouple

would be suitable for use in a 2,000 degree F (1093 C) furnace application.

That is assuming it actually works.

Figure 12

Figure 12 shows how we can

insert our T/C wire into several ceramic insulators. Insulators of this type

come in a wide variety of sizes and shapes. Several were used in Figure 12

as an example.

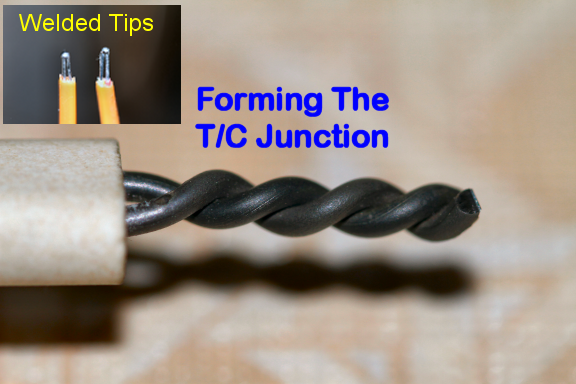

Figure 13

Figure 13 illustrates how

the actual junction of the dissimilar alloys is formed. I created a small

inset to the image showing some welded tips on AWG 22 thermocouple wire.

Thus far my very patient wife has been very good about my use of what is

“her” kitchen table. I feel it would be unwise to wander out to the backyard

shed and drag the Oxy / Acetylene welding outfit into her kitchen to weld

the tip of the junction on our new thermocouple. However, I should point out

that it is very, very important when welding T/C tips that only enough heat

be used to weld the tip and only at the tip. Excessive heat and heat not

applied correctly will alter the composition of the alloys creating a bad

and inaccurate thermocouple. I cannot stress enough the importance of this

step, especially when working with lighter gauge T/C wire.

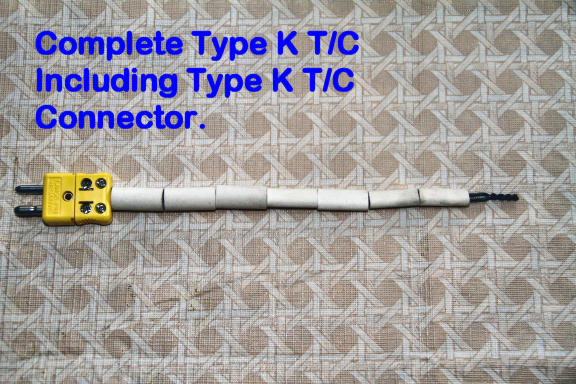

Figure 14

Figure 14 illustrates our finished product. A standard

thermocouple connector has been added. While not very pretty our

thermocouple should be functional, remember it is only an example. This

thermocouple could be inserted into for example a ceramic protection tube or

alloy protection tube. The next logical step would be to test our newly made

thermocouple. I guess I should come up with a way we can see if this thing

actually works. The classic statement applies at this point in that “it

looks good on paper”.

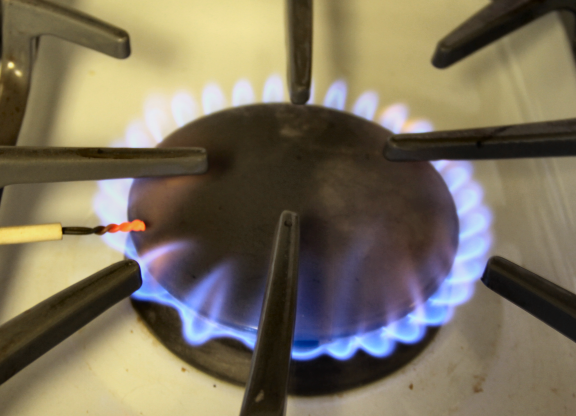

Figure 15

I have been informed by my

most patient wife that if anything goes wrong with using “her” stove this

will be my first and last blog. It could also mark the end of my life as I

know it. Figure 15 illustrates our new home manufactured thermocouple at the

kitchen table. The burner natural gas heat has our thermocouple radiating a

nice orange color so we can assume it is pretty hot at the tip junction.

Using some Type K thermocouple extension wire and a mating plug for our

thermocouple I have connected the thermocouple to an instrument suited for

measuring thermocouple output. Let’s take a look at thermocouple temperature

at the junction and see what we have here.

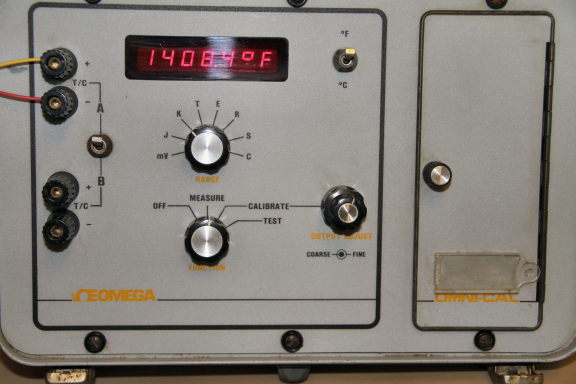

Figure 16

The device pictured in Figure 16 is an old but accurate and reliable

Omega manufacture Omni-Cal used in the testing and calibration of

thermocouples. This same instrument was marketed under several brand names

about 20 years ago. Every now and then I drag it into work and check the

calibration of it. For an instrument over 20 years old it still maintains

very good accuracy and I occasionally replace the battery NiCad pack. The

instrument is setup to measure a signal from the A input from a Type K

thermocouple and display the temperature in Degrees F. We can see our

thermocouple is reading a temperature of 1,408.4 degrees F. (764.67 C).

Prior to heating the thermocouple I did compare it to a precision mercury

glass thermometer at room temperature and it was perfect. Instruments like

this take into consideration the CJC we already discussed as does all modern

temperature indicating and measuring instruments.

Note the

connection point where the T/C extension wire mates with the instrument’s

connectors. Generally speaking when using thermocouple extension wire,

designed for low temperature environments, the red colored lead is the

negative. For example Type K is Red and Yellow, Type J is Red and White and

Type T is Red and Blue. In each case the Red lead is the T/C negative

output. I constantly see people new to the thermocouple world insist on

making the Red lead the Positive signal lead. Weird things happen when this

error is made.

Thermocouple Signal

Conditioning:

I like to

define “signal conditioning” as taking the signal you have and converting it

to the signal you want. We know a thermocouple outputs a small milli-volt

signal proportional to temperature, we know it is a non linear signal and we

know the thermocouple reference table’s reference to 32 degrees F (0.0 C).

One very

simple and yet very accurate means of conditioning the low milli-volt signal

from a thermocouple to something useable is a small device known as a

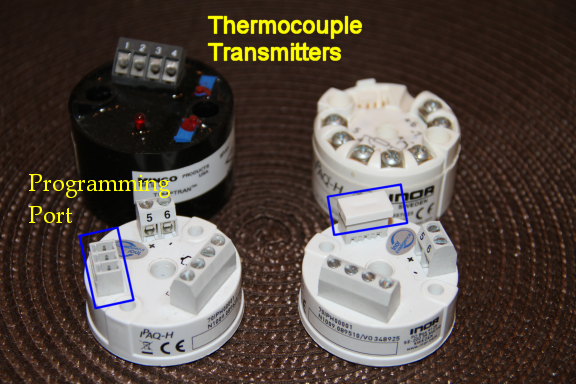

“Temperature Transmitter” a few images of which are shown in Figure 17.

Figure 17

These small devices available from a wide range of manufacturers can

take an input directly form a thermocouple and output signals like 0 to 20

mA, 4 to 20 mA, 0 to

5 volts, 0 to 10 volts as well as other outputs for a given temperature

range. The black device (upper left) was manufactured by Minco Manufacturing

or actually marketed by them and is about 20 plus years old. Units like this

were designed for a specific temperature range and output as well as

thermocouple type. Newer units offer programming options as to input, output

as well as working with mV inputs for example from strain gauges. These

devices also take care of all the linearization curves we looked at earlier

providing a nice clean linear output.